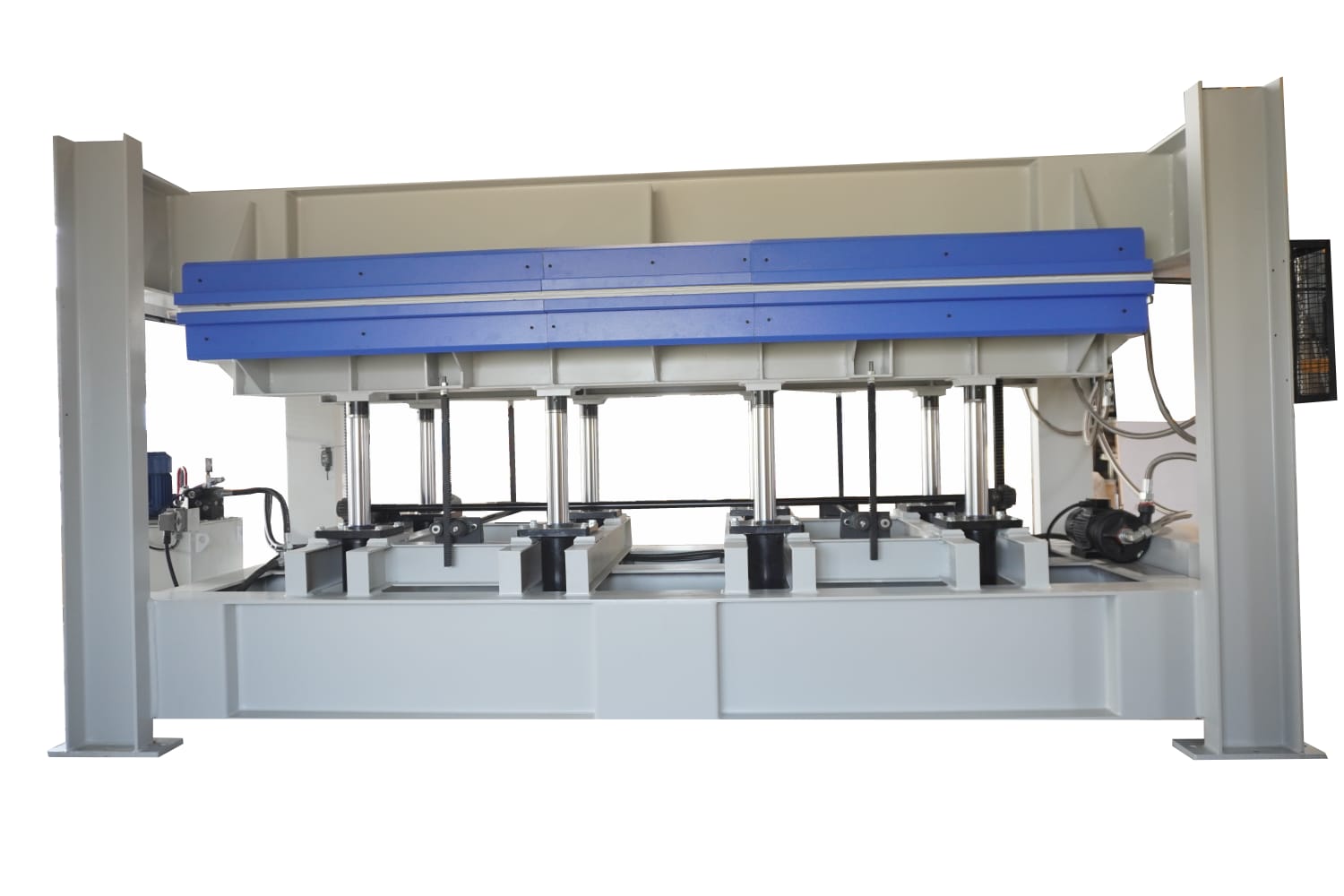

A woodworking cold press machine is a type of equipment used in woodworking to apply pressure to wood panels or assemblies without the use of heat. Unlike hot press machines, which use heat to accelerate the bonding process, cold press machines rely solely on pressure to create strong and durable bonds between materials.

Here’s how a woodworking cold press machine typically operates:

- Preparation: Wood panels or substrates are prepared by applying adhesive or glue to the surfaces that need to be bonded together.

- Assembly: The prepared panels are stacked together with any additional materials such as veneers or laminates placed in between.

- Loading: The stacked assembly is placed into the cold press machine.

- Pressing: The cold press machine applies pressure to the assembly, compressing the layers together and allowing the adhesive to bond the materials.

- Curing: After a specified period of time under pressure, the adhesive cures and solidifies, creating a strong bond between the materials.

Woodworking cold press machines come in various sizes and configurations, depending on the size of the panels being processed and the specific requirements of the woodworking project. They are commonly used for applications where heat-sensitive materials are involved or where a slower, more controlled bonding process is desired. Cold press machines are essential for producing high-quality wood products such as furniture, cabinetry, and decorative panels.